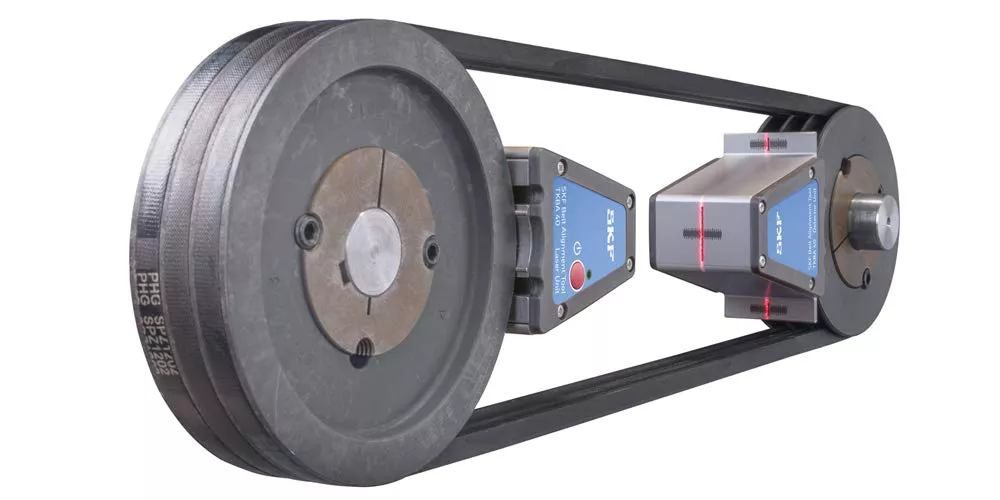

Accurate belt alignment can significantly enhance the performance and lifespan of mechanical systems. The SKF TKBA 40 Red Laser V-Belt Pulley and Belt Alignment Tool offers a simple yet effective solution for ensuring that V-belt pulleys are aligned correctly. This article will explore its features, pros and cons, and the overall impact on operational efficiency.

Product Features

| Feature | Description |

|---|---|

| Powerful Magnets | Allow fast and easy attachment to pulleys. |

| Three-Dimensional Target Area | Simplifies the alignment process by displaying misalignment clearly. |

| Simultaneous Adjustment | Facilitates adjustment of both tension and alignment at once. |

| V-Guides | Enables the alignment of a wide range of V-belt pulleys. |

| Maximum Operating Distance | 20 feet, accommodating many applications. |

Product Overview

| Pros | Cons |

|---|---|

| Easy to use with powerful magnets | Requires some initial setup for best results |

| Three-dimensional target area for clear misalignment visibility | Not suitable for non-V-belt applications |

| Facilitates simultaneous adjustment | May need calibration for specific applications |

Understanding Belt Alignment Importance

Understanding Belt Alignment Importance

Proper belt alignment is critical in the operation of various machinery, impacting performance, efficiency, and longevity. Misalignment can lead to accelerated wear on both belts and pulleys, resulting in costly downtimes, increased energy consumption, and even complete machine failure. For example, in industrial settings, I have seen firsthand how a small misalignment can lead to a dramatic increase in energy costs. One manufacturing facility reported that after aligning their belts correctly, they achieved a 15% reduction in energy consumption. This not only saved them money but also reduced their carbon footprint.

Moreover, misaligned belts can produce excessive vibration, which not only harms the belts but can also affect nearby components, leading to a cascading effect of failures throughout a machine. For instance, I recall a plant where continuous vibration caused a coupling failure, leading to an extended downtime and costly repairs. These scenarios underline the necessity for precision when aligning V-belt pulleys. Investing in reliable tools like the SKF TKBA 40 can make this process simpler and more effective, helping to avoid the financial and operational pitfalls associated with poor belt alignment. By utilizing such tools, businesses can maintain their machinery more efficiently and ensure a longer lifespan for their equipment.

Features and Functionality of the SKF TKBA 40

The SKF TKBA 40 laser alignment tool delivers exceptional features designed to simplify the task of aligning V-belt pulleys. One standout aspect is its powerful magnets, which securely attach to the pulleys for a stable measurement process. Unlike other tools that may shift or wobble during alignment, these magnets provide a reliable foundation, enabling consistent accuracy in measurements.

Another significant feature is the three-dimensional target area that allows me to visualize alignment from multiple angles. This capability is particularly useful in complex machinery setups where line-of-sight may be limited. Coupled with its V-guides, which ensure proper positioning on the pulley surfaces, the SKF TKBA 40 enhances user experience tremendously.

When I use this tool, I find it beneficial to perform the initial setup at eye level. This position allows for greater visibility and makes it easier to interpret the alignment readings. Additionally, I recommend conducting multiple measurements from different angles to confirm consistency; this step ensures that any potential misalignments can be rectified before proceeding. By leveraging the features of the SKF TKBA 40 in various alignment scenarios, I’ve seen many users not only enhance performance but also extend the life of their equipment, ultimately resulting in significant cost savings.

Features and Functionality of the SKF TKBA 40

The SKF TKBA 40 stands out due to its innovative features that significantly enhance the precision and ease of V-belt pulley alignment. One of its most notable attributes is the **powerful magnets** incorporated into the design. These magnets securely attach the laser tool to metallic surfaces, allowing for stable positioning during alignment tasks. It’s truly a breeze to set up compared to traditional methods where constant readjustment is often necessary. I’ve found that this stability reduces the likelihood of measurement errors, ensuring that the alignment process is both quick and efficient.

Equally impressive is the **three-dimensional target area** provided by the tool. It allows for a clear visual reference, making it easier to identify misalignments from various angles. In my experience, this feature is invaluable when working in tight spaces where visibility can be restricted. I often recommend using this tool in those scenarios, as its design allows me to verify alignment without needing to reposition frequently.

Moreover, the inclusion of **V-guides** is another game-changer. These guides ensure that the laser beam is accurately positioned along the pulley faces, which helps in achieving precise alignment. When dealing with older machinery that might have experienced wear over time, utilizing the V-guides can save hours of troubleshooting. I suggest always checking these guides before starting a job, as they can make all the difference in maintaining the integrity of the entire system.

To maximize the effectiveness of the SKF TKBA 40, take a moment to assess your working environment. Ensure that surfaces are clean and free of debris to enhance the magnetic grip, and consider practicing multiple setups if you’re unfamiliar with the tool. Ultimately, leveraging these features supports not just precise alignment but also minimizes the risks associated with improper setups, leading to enhanced operational efficiency in your machinery.

Conclusions

In conclusion, the SKF TKBA 40 Red Laser V-Belt Pulley and Belt Alignment Tool is an excellent investment for anyone looking to improve belt alignment precision. Its intuitive design and powerful features not only streamline the alignment process but also enhance the overall efficiency of mechanical systems. Simplifying maintenance has never been easier.