The TrivdPro Oscillating Tool Blades are designed for professionals and DIY enthusiasts alike, offering versatility and durability for various cutting needs. In this article, we’ll dive into the features that make these blades an essential addition to your toolkit and explore their performance across different materials.

Product Features

| Feature | Description |

|---|---|

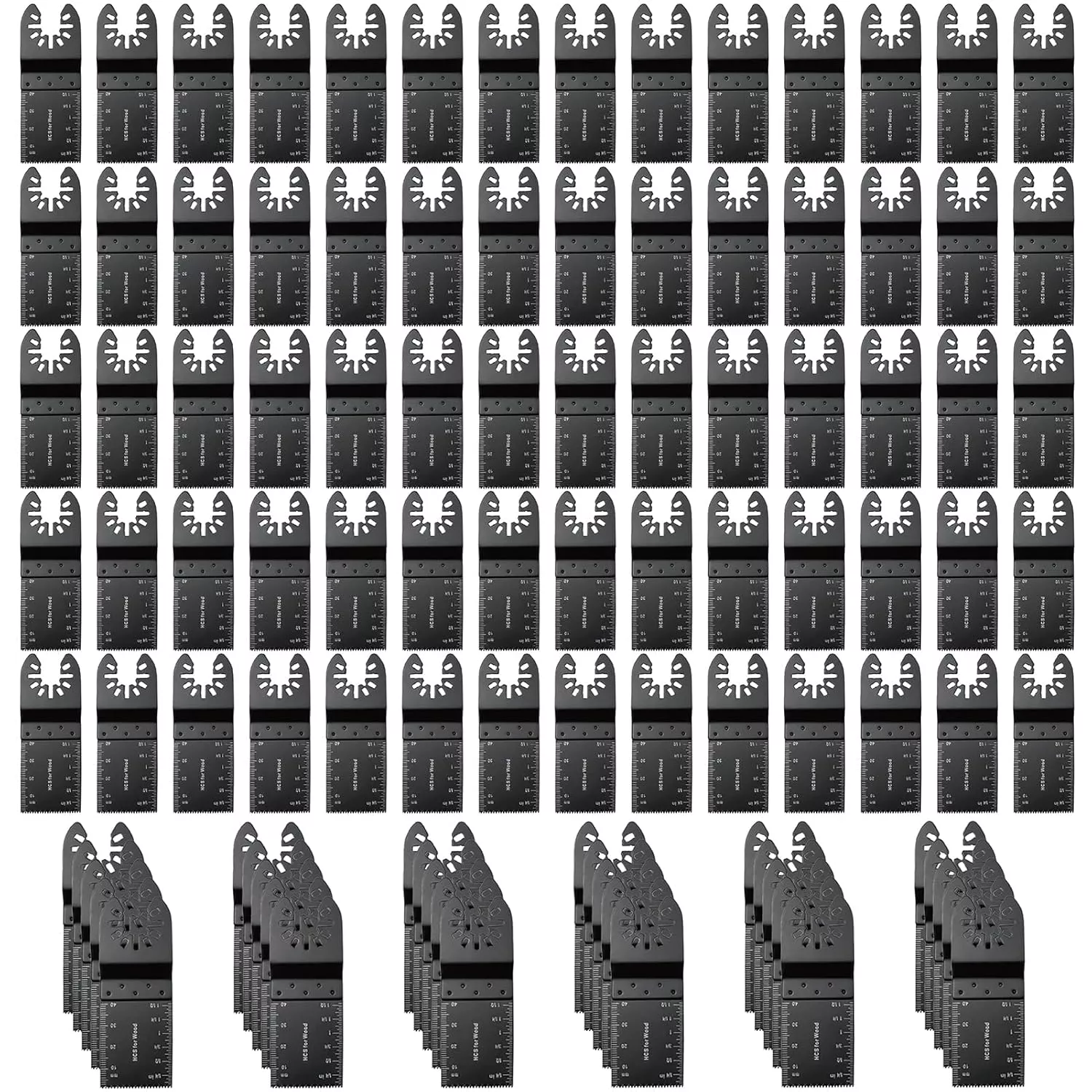

| Wide Range Of Use | This kit contains 50 oscillating tool blades suitable for cutting wood, soft metal, and plastic. |

| Special Design for Precision Cutting | Built-in length markers on both sides for accurate cuts; manufactured with a durable cutting edge. |

| Durability | Made from High Carbon Steel and Stainless Steel for superior wear tolerance and life. |

| Universal Compatible System | Compatible with many brands including DeWalt, Milwaukee, Ryobi, and more; excludes Bosch MX30. |

| Warm Suggestion | Not suitable for hard metal materials, as this affects both life and cutting effect. |

Product Overview

| Pros | Cons |

|---|---|

| Versatile for various cutting materials | Not suitable for hard metal materials |

| Universal compatibility with many tools | Durability may vary with heavy use |

| Affordable pricing for bulk purchase | Short lifespan for extensive cutting jobs |

Understanding Oscillating Tool Blades

Understanding oscillating tool blades opens up a world of efficiency and precision in various cutting applications. These blades operate through a unique oscillatory motion that allows for rapid side-to-side movement, enabling them to tackle tasks that would be challenging with traditional rotary tools. This mechanism grants incredible versatility, allowing users to make cuts in tight spaces, sand surfaces, or scrape materials with remarkable accuracy.

Compatibility is a crucial factor when it comes to oscillating tool blades. Not all blades fit every oscillating tool, so it’s essential to check that a specific blade is designed for your particular tool model. This ensures optimal performance and minimizes the risk of damage. Furthermore, blade materials—often ranging from high-carbon steel to bi-metal construction—greatly impact cutting capabilities and durability. For instance, high-carbon steel may work for softer materials but could wear out quickly when tackling tougher jobs, while bi-metal blades offer the robustness required for more demanding projects.

When comparing oscillating tool blades to other cutting tools, their multifaceted skill set stands out. Other tools may excel in one area, but the efficiency, versatility, and precision offered by oscillating blades make them indispensable in a modern toolkit, especially for DIY enthusiasts and professionals alike.

Evaluating the TrivdPro Tool Blades

When evaluating the TrivdPro Oscillating Tool Blades, I found that their specific features really stand out in a crowded market. The blades are designed with precision-engineered teeth that enhance cutting efficiency, making them ideal for various materials such as wood, metal, and even plastic. Users often rave about their performance statistics, with many noting that they experience less wear and tear over time compared to competitors. In particular, the durability of these blades is impressive; they are constructed from high-quality steel that resists bending and breaking, fostering longer-lasting use.

I also noticed that the versatility of TrivdPro blades sets them apart. Unlike some brands that specialize in one material, TrivdPro offers a diverse array of blade options, allowing users to tackle multiple projects effectively. For instance, I’ve seen users switch seamlessly from cutting trim to handling tougher drywall tasks without needing to change blades.

However, it’s essential to consider some drawbacks. While the performance is exceptional, the price point may be slightly higher than lower-end brands. Yet, I argue that the investment pays off in terms of quality and longevity. Overall, TrivdPro oscillating tool blades clearly outperform many alternatives, making them a valuable addition to any toolbox.

Conclusions

In summary, the TrivdPro Oscillating Tool Blades provide exceptional versatility and compatibility, making them a worthy investment for both professionals and DIY enthusiasts. While they may have limitations in cutting hard materials, their precision and affordability make them a powerful tool in any toolkit.